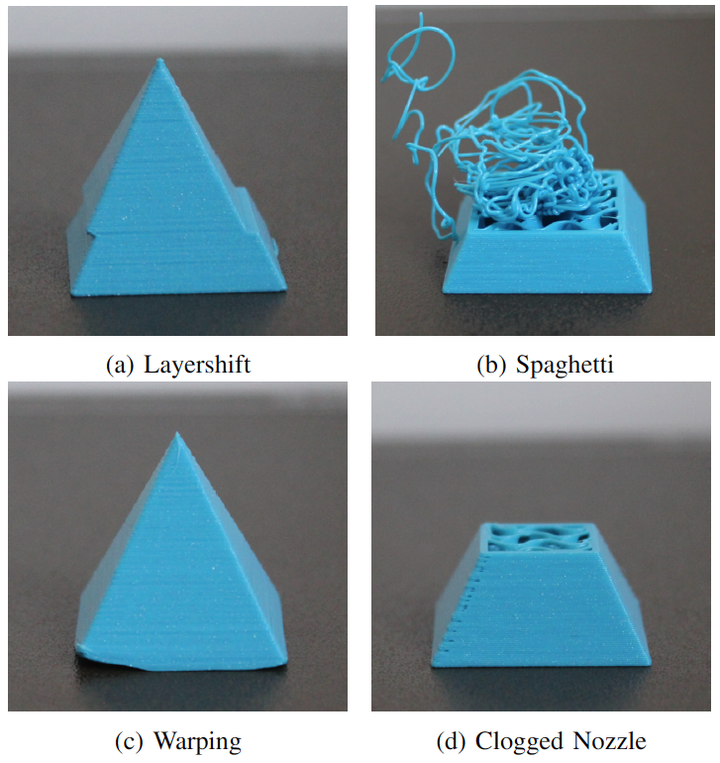

Different errors during Fused Filament Fabrication.

Different errors during Fused Filament Fabrication.

Abstract

Additive manufacturing (AM) is increasingly used in production as possibilities like no geometrical constraints, fabrication of complex assemblies in a single piece and fast iteration delivers a huge additional benefit. However, the printing process is still prone to errors, even though the technology is several decades old. Depending on the object and the used material a complex set of parameters have to be chosen to produce a durable object that fulfills the requirements. The errors can occur at any time during the print process so the current state has to be checked regularly. This is currently done manually as only a few printers use sensors for error detection. But most of them only check for hardware faults like axis misalignment or blocked filament flow control. Meanwhile, a lot of research has been done to improve the material, the printer’s hardware as well as to detect errors during the printing process. The goal of this publication is to summarize the current state of the art in terms of the error detection aspect. Therefore, we studied multiple techniques to detect errors like using different sensors concepts, classical sensor data processing, and neural networks. Several promising approaches exist, but so far, only a few are currently used in some commercially available printer. As the research continues, further approaches will be developed and might also be considered in production.