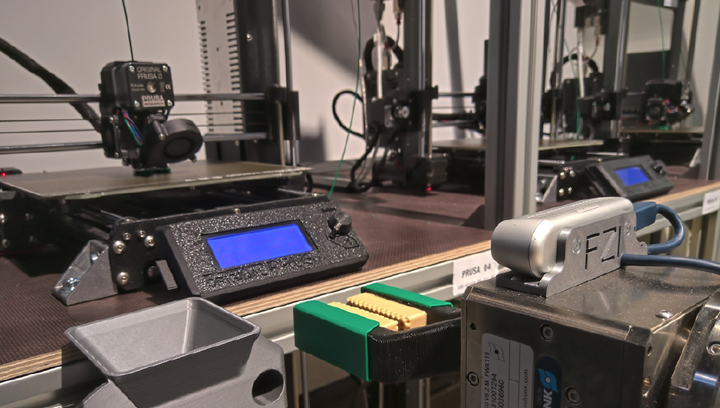

To check errors during the printing process at multiple 3d printers a light-weight robot is carrying a camera. Its horizont is aligned with the current height of the nozzle to get an optimal view at the nozzle and the current layer of the printed object.

To check errors during the printing process at multiple 3d printers a light-weight robot is carrying a camera. Its horizont is aligned with the current height of the nozzle to get an optimal view at the nozzle and the current layer of the printed object.

Abstract

The economic importance of additive manufacturing utilizing Fused Deposition Modeling (FDM) 3D-printers has been on the rise since key patents on crucial parts of the technology ran out in the early 2000s. Altough there have been major improvements in the materials and print quality of the printers used, the process is still prone towards various errors. At the same time almost none of the printers available use build in sensors to detect errors and react to their occurrence. This work outlines a monitoring system for FDM 3D-printers that is able to detect a multitude of severe and common errors through the use of optical consumer sensors. The system is able to detect layer shifts and stopped extrusion with a high accuracy. Furthermore additional sensors and error detection methods can be easily integrated through the modular structure of the presented system. To be able to handle multiple printer without the same amount of sensors, the sensor was added to the tool center point (TCP) of a robot.